Materials Science of Processing

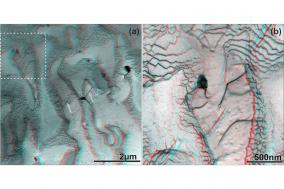

In recent years, our group succeeded in clarifying many open questions, because we were able to produce materials on our own on a laboratory scale. This helped to understand the creep behavior of Cu alloys with and without Bi and Sb additions, which segregate to grain boundaries. This also contributed to a new understanding of the influence of excess Ni on the martensite start temperatures in NiTi shape memory alloys. Jan Frenzel carries forward these studies. In the reporting period, he has established a materials processing group he heads as Ad-junct Professor. The processes governing microstructural evolution during solidification and postcast thermomechanical treatments have become an important element of research. Toward the end of the reporting period, a new seeded Bridgman technique was established that allows the processing of laboratory-scale bars of single crystal superalloys. In combination with scale-bridging characterization methods, this enables the identification of elementary processes that govern microstructural evolution (e.g. competitive dendrite growth during solidification and the way in which dislocations nucleate when a melt solidifies).