Research-Based Learning - Exp.1: Creep Damage at Grain Boundaries

At the Ruhr University Bochum, research-based learning is an important element of the image the institution has of itself, with the result that students are integrated into ongoing research projects. As an example, the following illustrates in concrete terms just such integration into the work conducted at the Chair of Materials Science and Engineering.

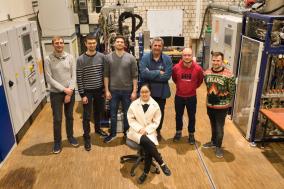

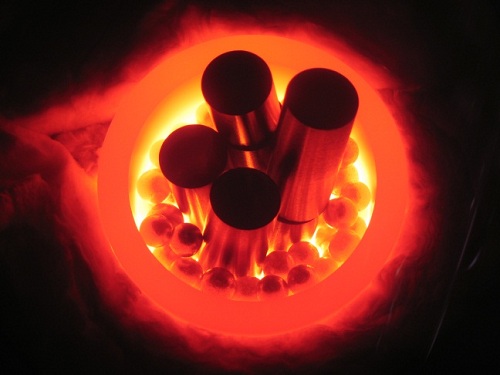

Figure 1: Melting alloys in a vacuum induction furnace.

This example is concerned with the damage to pores caused by creep. If materials are subject to load at high temperatures, small pores can form on grain boundaries, which grow and ultimately lead to creep fracture. This limits the service life of high temperature components and is therefore technically of the utmost importance. A precise understanding of the formation and the development of these pores is therefore vital. Two factors play a crucial role here: (1) The difference in orientation between the two grains that are separated by the grain boundary. (2) The chemistry of the grain boundary, in particular the presence or absence of third elements.

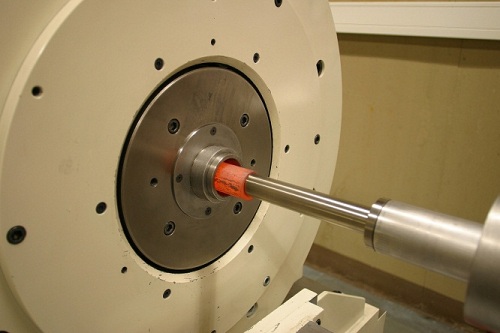

Figure 2:Cylindrical cast block being inserted into a rotary swaging machine.

In order to investigate this question, Cu, CuBi and CuSb alloys were melted and thermo-mechanically treated so that a similar grain size resulted in all three systems. The Bi and Sb accumulated at the grain boundaries, so that the three systems could be compared: polycrystalline pure copper and copper with Bi or with Sb at the grain boundaries. Students were able to perform a number of pieces of work, even at this early stage of the research project. For example, the melting of alloys can be examined; melting experiments are performed in a vacuum induction furnace, the molten ingots are then investigated for chemical homogeneity.

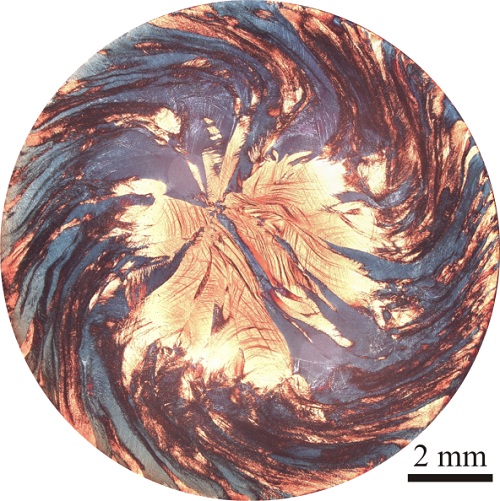

Figure 3:CuBi ingot after processing with the rotary swaging machine.

Furthermore, research projects can be carried out by students on thermo mechanical treatment and on setting a constant grain size.

Figure 4:Microstructure of pure copper after processing with the rotary swaging machine.

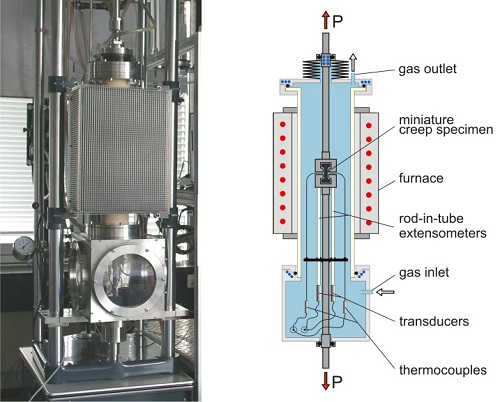

These are followed by creep tests; at the Chair of Materials Science and Engineering a special miniature creep specimen is used. Here too, there is more than enough material for scientific investigation to engage the enquiring minds of our students.

Figure 5:Conducting creep tests on miniature creep specimens in an inert gas atmosphere.

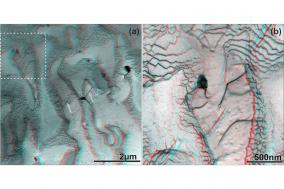

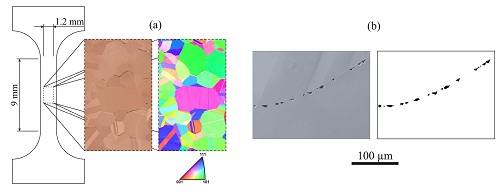

In a careful microscopic examination using orientation-imaging scanning electron microscopy, grain boundaries with creep pores are metallographically investigated.

Figure 6:Examples of the evaluation of creep pore damage

in a miniature creep specimen.

For example, the results obtained show how the creep pore damage depends upon the crystallographic nature of the grain boundary and on the chemistry of the grain boundary. During the course of a semester, Bachelor's, or Master's thesis in this field, students are familiarised with important manufacturing processes (melting metallurgy, forming). The students delve into microscopic methods (light microscopy, scanning electron microscopy). They learn how to perform creep tests and how to metallographically examine creep specimens. In particular, they become acquainted with orientation imaging scanning electron microscopy. They develop a good appreciation of processes that determine the service life of high temperature materials.