Research-Based Learning - Exp.2: Functional Fatigue of Shape Memory Actuators

At the Ruhr University Bochum, research-based learning is an important element of the image the institution has of itself, with the result that students are integrated into ongoing research projects. In a second example, we show how this might look in practice.

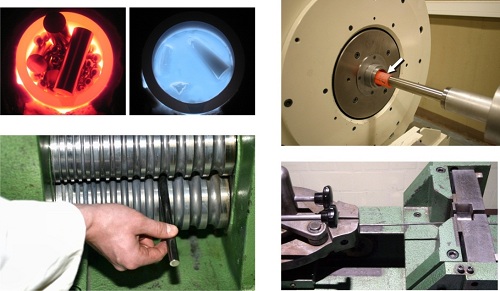

Figure 1: The manufacture of NiTi shape memory wires: melting, swaging, rolling into a round crosssection and drawing wire.

These are the fascinating shape memory alloys which are capable of remembering their form even after undergoing severe deformation. When they are heated, they return to their original form. This one-way effect can be utilised in actuator applications. Shape memory actuators are manufactured so that they switch at certain given temperatures. These manufacturing processes enable one actuator to open the hot water valve in a coffee machine at 100 ° C, while another opens a greenhouse window at 40 ° C. A shape memory actuator has the advantage, compared with a classic motor-driven actuator, that it is extremely compact and works absolutely free of any vibration, since it only responds to changes in temperature. At the Chair of Materials Science and Engineering, we are able to manufacture NiTi wire on-site and wind it to form springs ourselves.

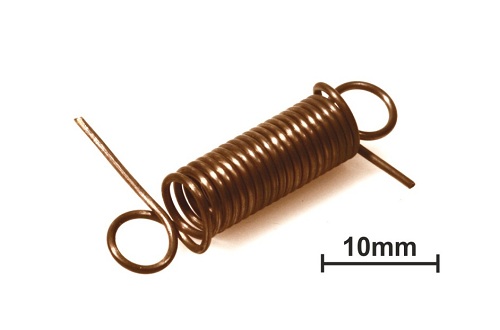

Figure 2: Actuator spring, which was wound at the Chair of Materials Science and Engineering. Heat treatment is then used to imprint the shape into its metallurgical memory.

At the Chair of Materials Science and Engineering, the process routes for

the production of actuator springs have been optimized as a part of the various research activities conducted by the students. As part of the project work carried out by our students, a test rig was built that enables the investigation of functional fatigue in shape memory alloys. To this end, a fatigue test rig was developed at the Chair of Materials Science and

Engineering by postgraduates and students.

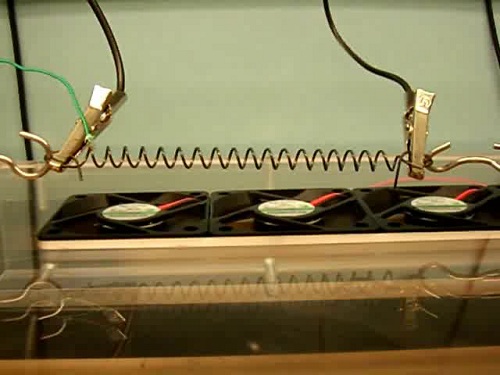

Figure 3: Shape memory actuator spring on the test bench

at the Chair of Materials Science and Engineering.

Shape memory actuator spring on the test bench at the Chair of Materials Science and Engineering.

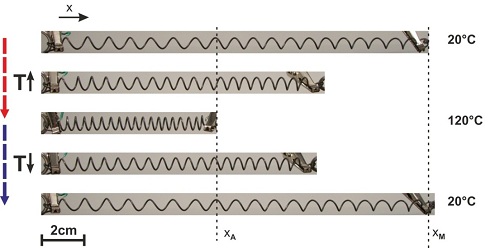

Figure 4: Changes to the shape of the actuator spring during heating and cooling.

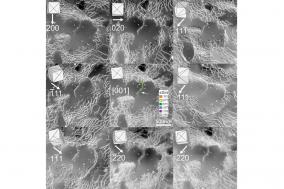

There is also a great deal of interest in the microstructural analysis of the elementary processes that are responsible for the functional fatigue of shape memory springs. To this end, examinations using both the scanning electron microscope and the transmission electron microscope are carried out. Microscopic studies of this kind would certainly be interesting topics for Bachelor's and Master's theses.

Figure 5: Production (ingot, rod, wire, spring) and fatigue (irreversibly deformed spring after many heating / cooling cycles) of

NiTi actuator springs.